CNC lathe | Robot

Product

Fast aging:

时效快:The company has a professional maintenance technical team;

The division of labor for mechanical maintenance, design transformation, precision scraping, hoisting and transportation and parts supply is clear, pragmatic and rigorous;

Equipped with a special service vehicle to ensure high and smooth maintenance efficiency, and perform their duties to escort your equipment normally;

Excellent price:

价格优:In the maintenance process, on the premise of customer interests first and ensuring quality, follow the principle of increasing revenue and reducing expenditure, and do not expand the maintenance workload;

Avoid small faults, pay high prices for maintenance, respond quickly, shorten the shutdown cycle with efficient maintenance level, purchase parts from the source, multiple savings, and naturally enjoy high returns;

Good reputation:

信誉佳:We always adhere to the good faith management, truthfully reflect the fault situation, never exaggerate the fault point, so that you can understand the consumption;

In case of failure during the warranty period, we will repair it free of charge at the fastest speed. Now we have established a good reputation in the customer group;

Regardless of cost, customer first:

不惜成本,顾客至上:Adopt full warranty, check the faults that may occur during maintenance, replace all defective parts, and eliminate hidden dangers at one time;

The Machining Department of the mechanical part can solve the urgent and difficult parts through forging, quenching, carburizing and gear grinding processes. The control part adopts brand cables and brand electrical components to save energy and environmental protection and think for you wholeheartedly;

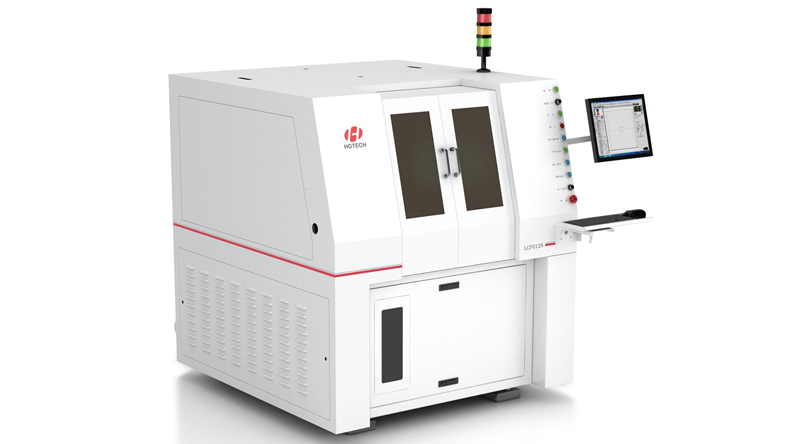

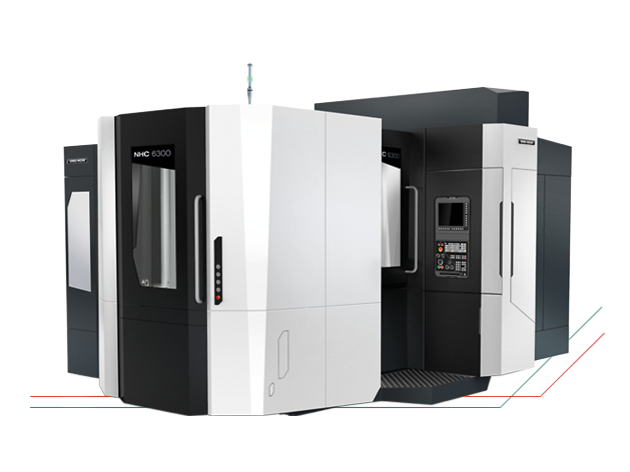

Company profile

Founded in 1997, the company is a senior enterprise integrating technical consultation, installation, commissioning, overhaul, maintenance and parts purchasing of industrial equipment. It mainly solves the parts purchasing of professional equipment such as power, shipping, hardware mold, sheet metal, injection molding and electronics for you; Equipment installation and commissioning; Transformation of machine tool system; Mechanical accuracy recovery; Hydraulic and pneumatic pressure, server, servo motor, frequency converter, I / O board, PLC and man-machine surface maintenance. The types targeted are {robot, precision carving machine, computer gong, plate shearing machine, bending machine, spring machine, punching machine, casting machine, deep hole drill, gear hobbing machine, machining center, EDM machine, five axis linkage, nano machining machine, high-speed milling machine, laser cutting machine, internal and external grinder, high-pressure cleaning machine, gantry machining center, profile machining center, CNC multi head punch Slow wire cutting, plasma cutting machine, central air conditioning, air compressor, ultrasonic welding and cleaning machine. We have been growing for more than 20 years, with high-quality products and excellent technical team to provide you with excellent technical support and satisfactory after-sales service. If you need our help or cooperation, welcome to inquire!

See more2021-11-27

2021

11-27

Repair of mechanical parts - welding repair of steel parts

The welding repair of steel parts has its inherent welding characteristics. For specific work, detailed pre welding inspection and preparation shall be carried out. Before welding, fully understand the working state of the workpiece, the cause of damage, the shape and size of the damaged part, and map and calculate the workpiece if necessary. The crack source must be found out in order to eradicate the root cause and repair the symptoms. Preparation before welding is to degrease and rust the welding repair part in advance, and remove the fatigue layer to expose the metallic luster; Provide reliable shielding protection for non welding repair parts; The easily deformed workpieces shall be placed and paved, and some shall also adopt the immersion heat dissipation method; Arc striking plate shall be set for those with narrow release position and inconvenient arc striking; Open appropriate groove; Reasonable preheating of materials with high carbon equivalent, etc

2021-11-27

2021

11-27

Repair of mechanical parts - how to drill crack prevention holes in gas welding repair

Ask:Repair of mechanical parts - welding repair of parts

11-29

Answer:Welding repair process has a wide range of adaptability, and can repair parts with various materials and types of defects, and is not limited by process size, shape and workplace. At the same time, the repair product has high bonding strength, simple equipment and low cost. Its main disadvantage is the high welding temperature, which will cause the change of metal structure and thermal stress.

Ask:Repair of mechanical parts - Methods of part inspection

11-27

Answer:Machine tool maintenance, CNC machine tool maintenance, equipment overhaul, parts inspection